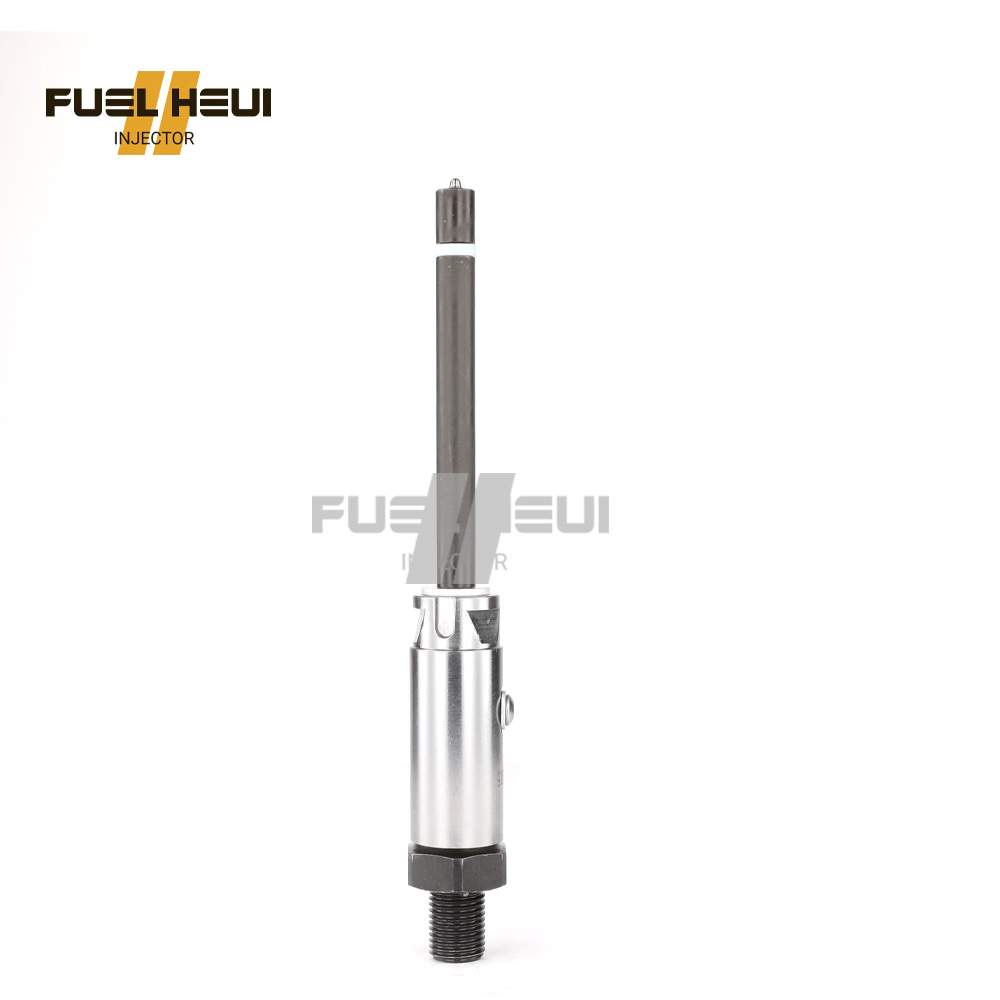

| Type | Mechanical Injector |

| Part Number | 8N-7005 |

| Series | 3300 Series |

| Quality | China Made New |

| SKU | G1F100008N7005 |

| Package Size | 22cm* 4cm *4cm |

| Weight Per Box | 0.4Kg |

WE GIVE YOU MORE

Lorem ipsum dolor sit amet, consectetur adipiscing elit。Ut elit tellus、luctus nec ullamcorper mattis、pulvinar dapibus leo。

Lorem ipsum dolor sit amet, consectetur adipiscing elit。Ut elit tellus、luctus nec ullamcorper mattis、pulvinar dapibus leo。

Owners Manuals

Lorem ipsum dolor sit amet, consectetur adipiscing elit.Utelit tellus,luctus nec ullamcorper mattis,pulvinar dapibus leo.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Utelit tellus, luctus nec ullamcorper mattis,pulvinar dapibus leo.

1. 8N-7005 HEUI Injector Introduction

1.1. 8N-7005 HEUI Injector Basic Information

| Title | 8N-7005 HEUI Injector 3300 Series China made new |

| SKU | G1F100008N7005 |

1.2. 8N-7005 HEUI Injector Common Part Number

(1) Injector Exchange Information

| Injector Part Number | Re-manufactured Part Number | Engraved Number |

| 8N-7005 | 0R-1740 | / |

| 8N7005 | 0R1740 | / |

| / | 0R-3418 | / |

| / | 0R3418 | / |

(2) Matching Information

| Car Model | Engine | Engine | Engine | Engine | Engine | Engine |

| PAVING COMPACTOR | CB-534 | CP-643 | CP-653 | CS-643 | CS-653 | / |

| CRAWLER LOADER | 963 | 973 | 977 | / | / | / |

| WHEEL BULLDOZER | 814B | / | / | / | / | / |

| WHEEL-TYPE LOADER | 930 | 930R | 930T | 936 | 936E | 936F |

| 950B/950E | 950E | 966C | 966D | 966E | 966F | |

| 966G | 970F | 972G | G936 | 950B | 966F II | |

| CRAWLER SKIDDER | 120C | 125C | 527 | D4HTSK III | D5HTSK II | / |

| WHEEL SKIDDER | 120C | 515 | 518 | 518C | 525 | 528 |

| 530B | FB518 | 528B | / | / | / | |

| ENGINE – MACHINE | 3304 | 3306 | / | / | / | / |

| PIPELAYER | 571G | 572G | / | / | / | / |

| GRADER | 120G | 12G | 12H | 12H ES | 12H NA | 140G |

| 140H | 140H ES | 140H NA | 143H | 14G | 160G | |

| 160H NA | 130G | 160H | / | / | / | |

| TRACK-TYPE TRACTOR | 140 141 143 4 4A 5 55 56 56H 57 57H 5A 5P 5S 6 6A 6S 6SU | 7 7A 7S 7S LGP 7SU 7U D4E D4E SR D4H XL D4H D4H III D5 | D5B D5E D5H D5H XL | D6D D6D SR D6E D6E SR D6F SR | D6G D6G SR D6G2 XL D6GC D6H D6H II | D6H XL D6H XR D7G D7H |

| CHALLENGER | 65 | 65B | 65C | 65D | 70C | / |

| WHEELED SELF-PROPELLED SCRAPER | 615 615C 615C II | 621E 621S | 627B 627E 627F | 637D 637E 639D | / | / |

| ARTICULATED UNLOADING TRUCK | D250B D25C D25D | D300B D300D | D30C D30D | D350C D350D D35C | / | / |

| ENGINE – INDUSTRIAL | 3304 | 3304B | 3306 | 3306B | / | / |

| EARTH MOVING COMPACTOR | 815B | 816B | / | / | / | / |

| EXCAVATOR | 215 215B 215C 215D 219 219D | 225 225B 225D 229 229D 235 | 235B 235C 235D 330 L 330 LN | 330-A 330-A L 330-A L 330-A LN | 350-A 350 L 350-A L E240 E300 | E300B EL240 EL300 EL300B |

| ENGINE – GENERATOR SET | 3304 | 3304B | 3306B | / | / | / |

1.3. 8N-7005 HEUI Injector Part Number Common Writing

8N-7005, 8N 7005, 8N7005, 0R-1740, 0R 1740, 0R1740, 0R-3418, 0R 3418, 0R3418

1.4. 8N-7005 HEUI Injector Parameter

HEUI Injector Adaptation System:Common Rail System

HEUI Injector Series:3300 Series

HEUI Injector Type:Mechanical Injector

Vehicle Configuration Information: Engines

HEUI Injector Size:20cm* 3.5cm *3.5cm

HEUI Injector Net Weight:0.32kg

HEUI Injector Gross Weight:0.4kg

HEUI Injector Quality:China Made New

HEUI Injector Package Size:22 cm* 4 cm *4 cm

HEUI Injector Type:Diesel Common Rail Injector

HEUI Injector MOQ:4 Pieces

2. 8N-7005 HEUI Injector Quality Control

(1)Injector Testing

All HEUI injectors are tested for electrical characteristics, accuracy, high temperature, low temperature, withstand voltage, leakage, durability, and various working conditions.

(2)Injector Assembling

For quality control during the production and installation process of HEUI injectors, our company strictly follows the standard product installation data and product installation steps for installation and testing, such as injector stroke test, injector solenoid valve tightening torque test, injector nozzle tightening torque test, etc.

(3)Injector Inspection

The factory inspection of the HEUI injector is undergone full inspection, random inspection, and batch inspection three inspections. Different brands of test benches are used to test the same HEUI injector for a total of more than three times for factory inspection, and the HEUI injector installation testing environment are progressed in dust-free workshop.

3. 8N-7005 HEUI Injector Customized Service

(1)Injector Customized ServiceCoverage: Meet the customized needs of OEM manufacturers for shell lettering, logo engraving, HEUI injector internal packaging, HEUI injector external packaging and labels customized, etc.

|

No. |

1 | 2 |

|

Image |

|

|

| Name | HEUI Injector Shell Engraving |

HEUI Injector Box and Label |

(2)Injector Customized Service Requirements:

The purchase of customized HEUI injectors are not less than 10 pieces.

The purchase of customized HEUI injector packages are no less than 1000 pieces.

When the Customized products involve the need of specify logo, the OEM manufacturer is asked to provide trademark authorization and the sample of logo image file.

- Once the customized HEUI injector is sold, it cannot be returned or exchanged if there is no quality problems.

4. 8N-7005 HEUI Injector Packing

Domestic Express Packaging:Usually wrapped in waterproof scotch tape, such as picture No.1.

International Express Packaging:Wrapped with waterproof yellow tape After wrapping the black protective film, such as picture No. 2.

Pallet Shipping:Use fumigation free and recycling trays that meet export requirements, and use white wrapping protective film to wrap and bind with cable ties for the outside, such as picture No. 3,also, the products can be packaged according to customers’ requirements.

- The packing tray is made of plastic and can be recycled.

- Transparent tape, yellow tape, black wrapping protective film, white wrapping protective film are non-degradable materials, please dispose of them properly.

- Minors are prohibited from using transparent tape, yellow tape, black wrapping protective film, and white wrapping protective film to avoid personal injury.

5. 8N-7005 HEUI Injector Warranty Instructions

(1)Product Warranty Conditions and Instructions

It is necessary to provide pictures, videos, or test reports detected by the HEUI injector inspection equipment as evidence to feed back to the salesman when the HEUI injector is abnormal during using.

Abnormal conditions are properly explained such as:1.Smoke, 2. Engine shake, 3. Difficulty starting the engine, 4. Engine noise, 5. oil leakage etc.

(2)HEUI Injector Warranty Coverage

Within 15 days after customer receives the 8N-7005 HEUI injector, if there is a performance failure and the product has no appearance damage, customer can choose to replace it or repair it;

If the 8N-7005 HEUI injector has performance problems during the warranty period (6-12 months), and it is confirmed that it is product’s problems after testing, you can contact our salesmen to replace the same model or a reworked product with the same performance for free;

If the HEUI injector house has obvious scratches, it can only be repaired and it will be returned as it is if the product is confirmed to be fault-free.

- Tips:For products not covered by warranty, Shumattcan provide paid maintenance services. For products after paid repaired, the same performance problem will havea free warranty period within 3 months from the date of repair

(3)Injector Out of Warranty Coverage

- The warranty period has expired.

- HEUI Injector failure caused by high temperature, high pressure, humidity, rain and snow, saline-alkali land, earthquake, and used in abnormal environment.

- Customer disassembles or repairs the HEUI injector personallyresultingin damage to the HEUI injector.

- HEUI Injector damage caused by man-made reasons (throwing, strong magnetic field magnetization, set fire).

- HEUI Injector failure orHEUIinjector is damaged caused by non-injector design, technology, manufacturing, quality and other issues.

- HEUI Injector failure due to system pressure exceeding system approved pressure.

- HEUI Injector failure caused by system voltage exceeding approved voltage.

- HEUI Injector failure caused by impurities (water, lead, aluminum powder, iron powder, sulfide) in the system fuel exceeding the standard requirements.

- HEUI Injector failure caused by not installing according to the tightening torque specified in the vehicle engine maintenance manual (the tightening torque is too large or too small).

- HEUI Injector failure caused by not following the installation angle specified in the vehicle engine maintenance manual.

- HEUI Injector failure caused by not following the cleaning requirements specified in the vehicle engine maintenance manual.

- HEUI Injector failure caused by failure to replace consumable parts as specified in the vehicle engine maintenance manual.

- HEUI Injector failure caused by not complying with the intake system fit clearance and exhaust system fit clearance requirements specified in the vehicle engine maintenance manual.

- Failure to replace the consumable parts and the fitting clearance of the oil inlet system pipeline and the HEUI injectorconnection in accordance with the fuel intake system specified in the vehicle engine maintenance manual.