About US

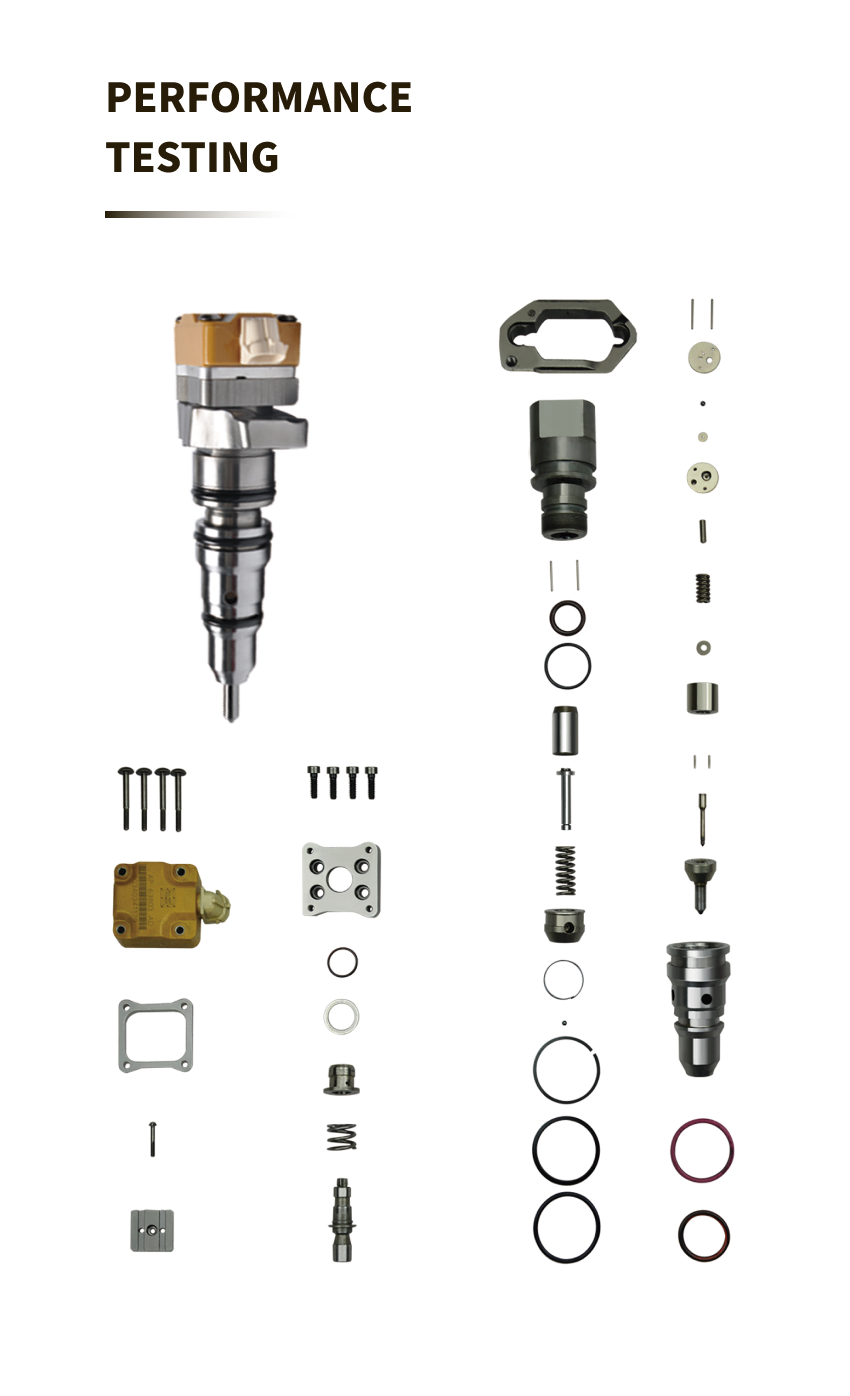

Performance Testing

The performance testing of fuel HEUI injector includes electrical characteristics, accuracy, the tolerance of high temperature, low temperature, pressure as well as leakage, durability and others working conditions testing. These conditions of each fuel HEUI injector will be tested before our fuel HEUI injectors are sent to customers.

Above are the tests needed to be done after the fuel HEUI injectors are finished producing. However, regular checking also very important to keep the fuel HEUI injector perform well.

In order to make sure the fuel HEUI injector works normally, there are some parts of fuel HEUI injector needed to be checked regularly and before installing to fuel HEUI injector.

① Check whether there is deformation, cracking, thread damage, quenching, leakage and rust in the guide sleeve, spring, gasket and tight cap of the fuel HEUI injector. The tight cap of the fuel HEUI injector must be replaced after being disassembled for more than 5 times, as shown in the following.

② Replace the tight cap of the fuel HEUI injector and the copper gasket of the fuel HEUI injector

③ Check whether the gap between the fuel HEUI injector needle and the fuel HEUI injector shell is within the standard range and whether it reaches the standard for use

④All parts should be examined for wear under a microscope at least 20 times larger

⑤ fuel HEUI injector tight cap deformation, cracking, thread damage, quenching, leakage, will lead to black smoke vehicle cap, fuel HEUI injector damage.

⑥fuel HEUI injector opening pressure greater than or less than the specified range may cause fuel HEUI injector damage.

⑦ Failure to replace wearing parts in time during maintenance may lead to fuel HEUI injector damage.

These are some precautions you need to know to maintain an fuel HEUI injector. If there are more questions about fuel HEUI injectors and other problems, you are welcomed to contact us, injectorheui.com will do the best to help you solve your problems.